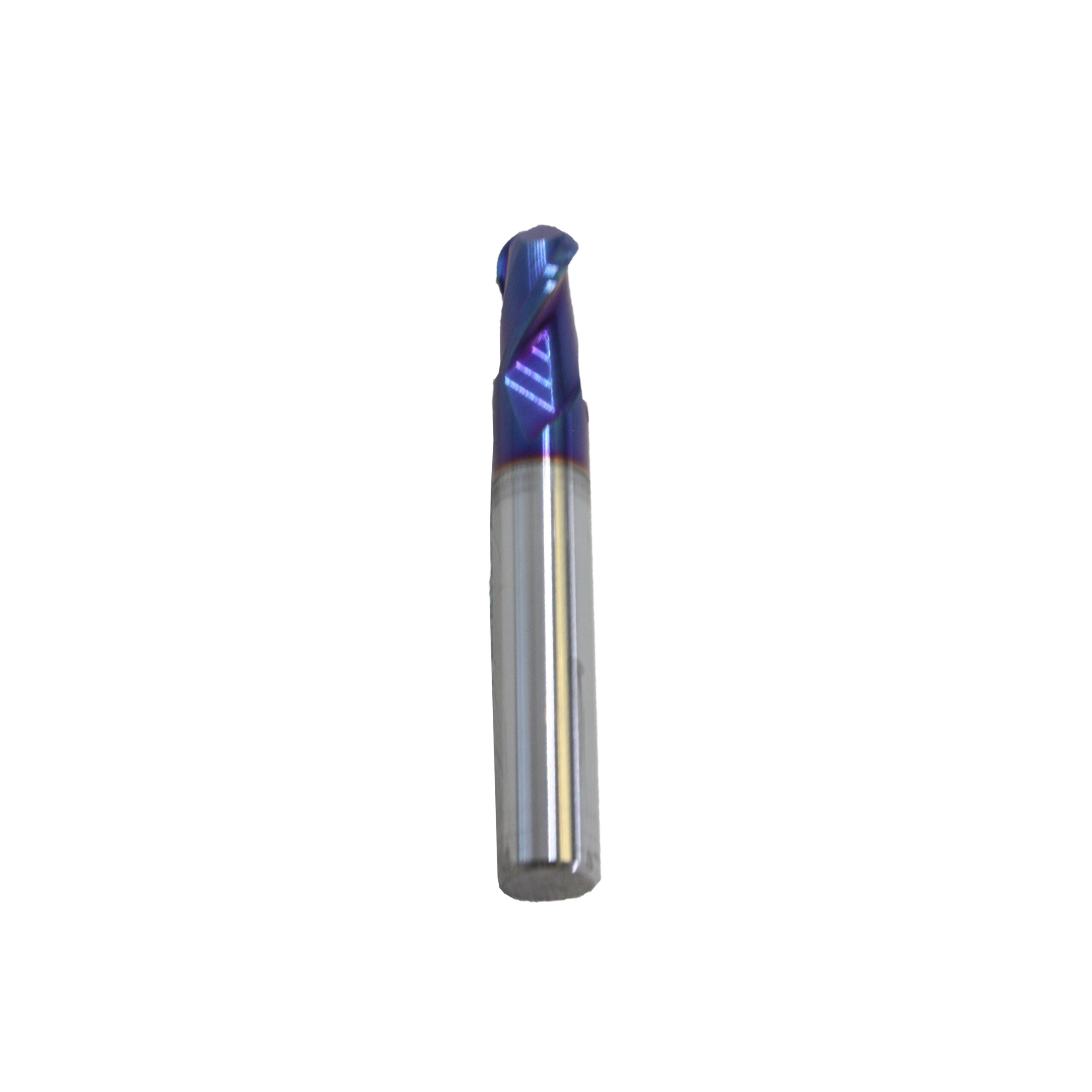

| DESCRIPTION | Ball End Mill |

|---|---|

| MATERIAL | HRC65 Carbide |

| DIAMETER | 6.0mm 2 Flute |

| LENGTH O/A | 75.0mm |

| FLUTE LENGTH | 13.0mm |

| SHANK | 6.0mm |

| FINISH | AITiSiN Coated |

| WEIGHT NETT/GROSS | 0.050kg |

| VOLUME | 0.0001cm |

Description

SKU : EM-7302406

Price per Unit

$44.00 (Exc GST)

$50.60 (Inc GST)

FEATURES:

* These ball nose 2 flute end mills are manufactured from quality HSS-M42 ( 8% Cobalt ) for durability and long service life

* Standard length General Purpose, 2 Flutes, Single End, ideal for radius Cutting, Right Hand Cut, Bright Finish

| Weight | 0.05 kg |

|---|---|

| Dimensions | 0.1 × 0.03 × 0.03 cm |

Specifications

Description

Reviews (0)

Be the first to review “BALL NOSE E/MILL: 6.0MM HRC65 CARBIDE COATED 2FL STD” Cancel reply

Shipping & Delivery

Related products

BALL NOSE E/MILL: 5.0MM HRC65 CARBIDE COATED 2FL STD

SKU:

EM-7302405

$38.00

BALL NOSE E/MILL: 6.0MM HRC65 CARBIDE COATED 2FL LONG

SKU:

EM-7302407

$28.00

BALL NOSE E/MILL: 12.0MM HRC65 CARBIDE COATED 2FL STD

SKU:

EM-7302412

$68.00

BALL NOSE: CARBIDE 4.0MM 2FL STD (INDEX)

SKU:

EM-7340040C

$22.15

*These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE 5.0MM 2FL STD (INDEX)

SKU:

EM-7340050C

$22.70

* These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE 6.0MM 2FL STD (USA)

SKU:

EM-7340060

$36.29

* These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes *

BALL NOSE: CARBIDE 1/4″ 2FL STD (INDEX)

SKU:

EM-7342500C

$26.68

* These ball nose end mills are manufactured from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide. The grain size ranges from 0 - 0,5 micron

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes

BALL NOSE: CARBIDE 5/16″ 2FL STD (USA)

SKU:

EM-7343125

$48.38

* These ball nose end mills are manufactured in USA from quality carbide for durability and long service life

* Solid carbide endmills for steel, cast, stainless steel, exotic materials, aluminum, non-ferrous materials and hardened steels

* These solid carbide endmills are made from ultra micrograin carbide.

* The grain size ranges from 0 - 0,5 micron and the coatings vary by application (TiAlN, TICN ).

* High performance, improved tool life, maximum cutting speed,

* Excellent wear resist and reliable quality, Cost effectiveness, Reduced wear ensures productivity, down time minimized, less tool changes

Reviews

There are no reviews yet.